Share this post on social media

Roadways play a fundamental role in modern society, facilitating transportation, commerce, connectivity and increasing economic development. However, amidst their undeniable benefits, the problem lies in conventional methods of road construction and maintenance, which come with alarming environmental consequences.

In this article, we will provide a comprehensive overview on the current issues and environmental challenges of traditional road building methods and materials, specifically bitumen, highlighting the benefits of BioBitumen as a sustainable alternative.

We had the privilege of conducting a very insightful interview with industry expert Frank Albrecht, product owner of BioBitumen, CEO of B2Square and Chief Technology Officer (CTO) of Biofabrik. With him, we will also shed light on our collaboration and the success story of bitumen substitute.

A post by Alice Frassin

What is bitumen?

Traditional asphalt primarily consists of aggregate (such as crushed stone, sand, or gravel) and a binder called bitumen.

Bitumen serves as the glue that holds the aggregate together, and it is a widely used material in road construction due to its functionality, strength and durability. However, it also has drawbacks and detrimental environmental effects.

Derived as a byproduct of crude oil extraction, bitumen’s utilization not only poses challenges during the extraction phase but also throughout its subsequent transformation processes.

Starting from its origins, the extraction of crude oil itself presents significant environmental consequences. Invasive drilling techniques disrupt ecosystems, endanger wildlife and contribute to carbon emissions, thereby exacerbating climate change.

Although one might argue that utilizing the byproduct of crude oil extraction for road construction represents a resourceful way to avoid waste, it is important to recognize that the transformation of this byproduct into bitumen has its own detrimental effects on the environment.

In fact, the environmental impact of the use of bitumen extends beyond crude oil extraction: converting the byproduct of crude oil refining into bitumen requires additional processes, each with its own environmental implications. Of particular concern is the substantial amount of CO2 emissions generated.

According to the German Environment Agency (Umweltbundesamt – UBA) 1 ton of bitumen is equivalent to 360 kilograms of CO2 emissions. In the same way, each ton of asphalt is 51 kilograms of CO2 emissions.

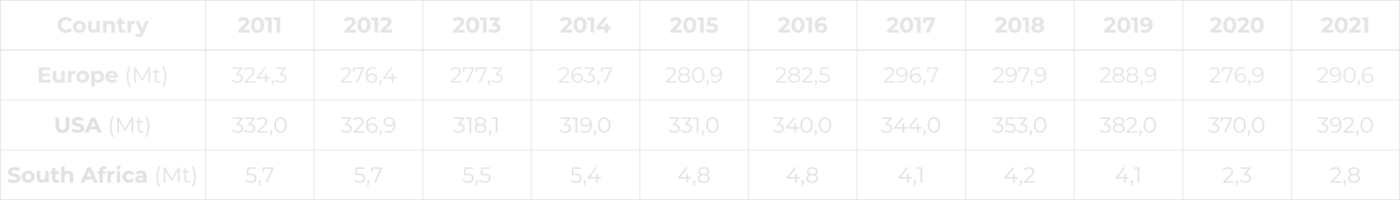

The Asphalt Pavement Association (EAPA) in “Asphalt in Figures 2021” reports that an average of approximately 624 million tons of asphalt are produced every year, only between Europe, the US and South Africa.

Estimating that each ton of asphalt contains 4% of bitumen, the yearly production of asphalt is estimated to produce an equivalent of 31,8 million tons of CO2 emission, with approximately 9 million tons from bitumen alone.

Even considering that sustainable practices might have been implemented to reduce the carbon footprint of the road construction industry, we can cut the total emissions per tons of asphalt in half and the total of CO2 emissions per year still would amount to more than 15 million tons.

In fact, it was stated that hot mix asphalt (HMA) production is the biggest contributor to CO2 emissions among all the considered LCA production and construction stages, with a GHG contribution of up to 39% from bitumen only.

While the environmental consequences of traditional road construction are undoubtedly significant, their impact extends far beyond this realm, permeating various aspects of our lives, encompassing social, economic, and political dimensions.

To maintain its workable consistency, bitumen needs to be supplied and transported in a heated state, with high temperatures rising up to +200°C. The transportation of bitumen to asphalt production plants and to street building locations thereafter poses several other challenges in its use.

This special condition results in not only substantial energy consumption and high amounts of CO2 emissions, but it also increases the probability of accidents in the work space, posing significant risks to the workforce.

In recent years, several incidents have highlighted the inherent dangers associated with transporting hot bitumen, which serve as sobering reminders of the risks faced by workers in the road construction industry.

In Schwechat, Austria, in 2017, a 56-year-old worker sustained severe burns while loading a semi-trailer with bitumen. That could have been caused by severe splashing that might have occurred in case there was residual water in the tank, causing the bitumen to erupt and pour over the worker.

Similarly, in 2021, Westerwald, a man suffered severe burns when liquid tar splashed onto his face during the emptying of a bitumen boiler. The exact cause of the accident remains unclear, underscoring the unpredictable nature of mishaps involving boiling bitumen.

In Zurich, Switzerland, in 2022, a bitumen container burst on a construction site, resulting in two workers being rushed to the hospital with severe burns. The incident occurred during paving work, and the clothes of the workers caught fire upon contact with the ignited bitumen.

These are only a few of the accidents that might occur, and these unfortunate events emphasize the potential hazards of working with hot bitumen, as even routine surfacing operations can lead to serious injuries.

Considering that roads and infrastructures are a necessity of economic development worldwide, the negative impact of bitumen is turning into a very big issue, especially in countries like Ukraine, Turkey and Syria which are currently facing the daunting task of urgently rebuilding their infrastructures.

According to the United Nations Office for the Coordination of Humanitarian Affairs (March, 2023), the recent earthquake in Turkey and Syria resulted in the collapse or heavy damage of 230,000 buildings in the former, while at least 10,600 buildings were completely or partially destroyed in the latter.

In Ukraine, on the other hand, since the onset of the war, the State Road Agency of Ukraine reports that approximately 24,000 kilometers of roads and around 300 bridges have been destroyed. Hence, more than 13% of Ukrainian roads are destroyed, estimating the cost of infrastructure damage to more than 130 billion euros.

Reconstructing the extensive infrastructure destroyed in these countries necessitates a significant amount of asphalt. Considering the scale of the damage, the estimated demand for bitumen and amount required quickly rises, and the consequent CO2 emissions add up to concerning numbers.

Various sustainable alternatives have emerged in recent years, aiming to mitigate the environmental impact of road construction. These alternatives include the use of recycled materials, such as reclaimed asphalt pavement (RAP) and recycled concrete aggregates (RCA), which help reduce the demand for virgin materials and decrease waste generation.

Solar roadways, another innovative solution, incorporate photovoltaic cells into road surfaces, harnessing solar energy for power generation and promoting renewable energy adoption.

However, while these current sustainable alternatives offer promising advantages, they also come with their own limitations.

Recycled materials, though beneficial, may have certain performance limitations compared to conventional materials. On the other hand, the use of solar roadways raises concerns regarding efficiency, durability, and cost-effectiveness on a large scale.

BioBitumen is a groundbreaking innovation in road construction that offers a sustainable and eco-friendly alternative to traditional bitumen. Unlike conventional bitumen derived from fossil fuels, biotumen is produced from organic waste and biomass, making it renewable and reducing the carbon footprint associated with road building.

One of the key benefits of BioBitumen is its superior quality and performance. It is a specific mixture of maltenes and asphaltenes, tailored to meet the individual needs of different roads and applications. This ensures that the specifications are met consistently, allowing for predictable and reliable performance.

Moreover, the use of BioBitumen contributes to industrial safety as it can be applied at lower temperatures, reducing the risk of emissions and aerosol inhalation for workers.

BioBitumen is an innovative solution that can effectively address certain environmental effects associated with road construction. While it may not solve the entire problem, it has the potential to significantly reduce one of the most detrimental effects: CO2 emissions.

Biofabrik’s first point of contact with BioBitumen was Frank Albercht, the CEO of B2Square, a leading company in the field.

We recently had an amazing interview with Frank, where we talked about our collaboration, his journey to becoming our CTO while leading his company B2Square, and the success story that BioBitumen is becoming.

BioBitumen is revolutionizing the asphalt industry by offering a sustainable solution with significant environmental and economic benefits: this collaboration to bring the product to the market combines Biofabrik’s expertise in sustainable solutions with B2Square’s product ownership and industry presence.

As a member of the Impact Family, B2Square shares Biofabrik’s commitment to making a positive impact on the environment, making them an ideal partner for bringing BioBitumen to the forefront of the road construction industry.

One of the notable advantages of biotumen is its CO2-negative nature. With a base derived from cashew nut shells, it actively sequesters carbon dioxide during its production and application.

This innovative feature not only reduces carbon emissions but also contributes to combating climate change.

CO2 negativity as well as the use of non hot spillable BioBitumen in transport makes it possible to use it in hard to reach and maybe constricted areas, opening new possibilities for road building across difficult terrain.

The principle of instant mixing on-site eliminates the need for storing and transporting large quantities of pre-mixed asphalt, promoting sustainability and reducing the carbon footprint of road construction projects.

In addition to its environmental benefits, biotumen offers energy efficiency advantages.

Unlike conventional bitumen that requires high temperatures for mixing, BioBitumen can be effectively mixed at lower temperatures. Lower energy costs are therefore a huge gain as there is no heating necessary during the process, outside of passive heating in the mixing plant.

The cold supply chain requires lower energy consumption compared to conventional bitumen, making transport logistics easier and more efficient, minimizing the emissions associated with heating during the mixing process.

Additionally, the adoption of biotumen significantly reduces the risk of work-related accidents caused by the transportation of molten hot bitumen, ensuring a safer working environment for workers involved in road construction.

Roads constructed with BioBitumen are designed to utilize the precise bitumen type that best suits the specific use case, resulting in enhanced durability and extended lifespan.

By carefully selecting and using the appropriate BioBitumen, the construction process can optimize the usage of resources, ensuring that only the necessary amount of material is used. This approach helps to minimize waste and maximize the efficiency and effectiveness of the road construction project.

Real-world applications of biotumen demonstrate its effectiveness in reducing carbon emissions and improving the overall environmental impact of road construction: dedicated projects in Germany, Italy, Netherlands Norway, South Africa and Japan give a hint of taste of how versatile and approachable we are on a global basis.

After considering the evidence of possibilities in Europe, sub-Saharan Africa, and Asia, your bitumen purchase decision suddently involves a political and ethical dimension.

Now, you are faced with a choice: do you want to keep supporting the traditional oil industry by buying their residual product, which might be utilized for share buybacks and crude oil exploration programs, or do you want to support an innovative GreenTech StartUp that aims to remove 450kt of CO2 from the atmosphere with your help?