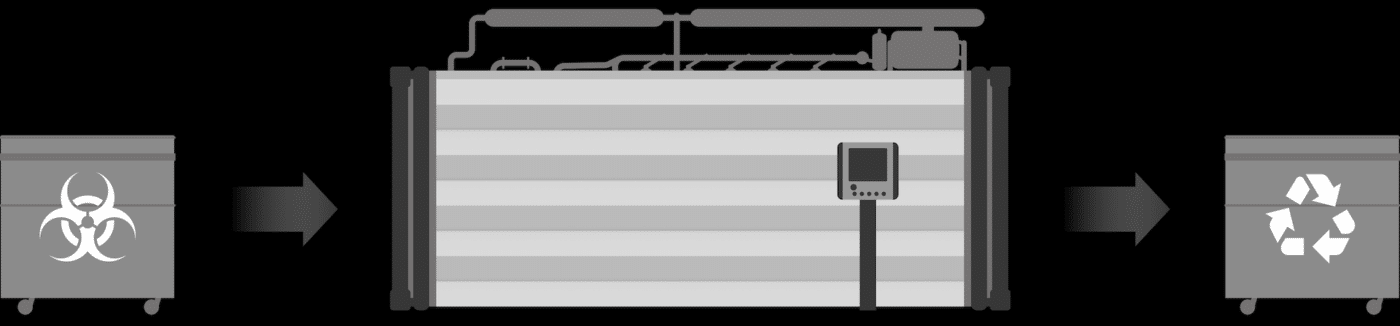

Eliminate high disposal costs and visit the successfully operating plant in Germany: The WASTX Cleanic turns up to 12 tons of hazardous waste per day into non-hazardous household waste – fully automated and highly profitable.

The plant operates in cycles of 8 hours which makes it possible to run three shifts per day.

The technology meets the highest standards of the Robert Koch Institute resulting in an easy approval.

Apart from loading and unloading, the process is fully automated.

Since the process uses only steam and vacuum and does not require a granulator, almost no repairs are necessary.

Through the implementation of the WASTX Clinic, supply chains are significantly optimized.

The experience of 27 of continuous operation, a improved plant has been developed.

Using hot water vapor viruses and bacteria contained in medical waste are disinfected, turning the hazardous medical waste into a non-hazardous household waste. Standard medical containers can be supplied closed and pop up during the process due to the vacuum chamber. After the treatment, the previously hazardous medical waste can be incinerated in standard incineration plants or submitted to higher-value material recycling.

This proven technology has been in operation for more than 27 years by a waste management company in Germany. Based on the experience of continuous operation, an improved plant has been developed, which has also been in operation for more than 2 years. Contact us for an exclusive personal tour of the WASTX Clinic in operation.

… until the next plant demonstration. Reserve your visit now!