Pyrolysis Plants

Pyrolysis plants, as part of the chemical recycling sector, are one of the fastest growing industries in the world. Commercial plants are already in operation in many countries. The market for pyrolysis plants is both diverse and complex. Therefore, in the following we compare established technologies, show which features are of particular importance when buying a pyrolysis plant and introduce the WASTX Plastic as a solution.

Pyrolysis Plants

Pyrolysis plants, as part of the chemical recycling sector, are one of the fastest growing industries in the world. Commercial plants are already in operation in many countries. The market for pyrolysis plants is both diverse and complex.

Therefore, in the following we compare established technologies, show which features are of particular importance when buying a pyrolysis plant and introduce the WASTX Plastic as a solution.

The Market of Pyrolysis Plants in Comparison

Low-Tech Pyrolysis Plant

Generally, there are various cheap options for pyrolysis plants (1-15 available on platforms. Both access and fast delivery for these plants are easily given. However, the pyrolysis oil that is produced often contains contaminants such as chlorine and sulfur. These have to be correspondingly treated at high cost to meet the market's oil standards or have to be disposed of. When it is used unprocessed, it harms the environment more than it actually serves.

Large Scale Pyrolysis Plant

The operation of large-scale pyrolysis plants (50-300 mt/day) is complex even in the initial phase, as the initial investment already amounts to several million euros. In addition, the profitability of these plants depends largely on the quality and price of the input materials, the reactor configuration and the type of end product. As a result, these systems require a high level of maintenance and can reduce profitability, especially during periods of downtime or system failure. (Goyal, 2021)

Modular Technology - WASTX Plastic

The WASTX Plastic modular structure offers decentral waste treatments due to its constainer-based design. Additionally, it enables plastic recycling starting from a low scale (1 mt/day) and can be upscaled as requested. This scalability ensures even large scale projects immune to failure, as if one module stops working, other modules will continue operating. Moveover, the customized pretreatment and clear feedstock requirements ensure a high-quality and sustainable output product which can be traded on the market.

|

Features

|

Large Scale Pyrolysis Plant

|

Low-Tech Pyrolysis Plant

|

Modular WASTX Plastic

|

|---|---|---|---|

|

Low fixed costs

|

|

|

|

|

Quick availability

|

|

|

|

|

Wide feedstock spectrum

|

|

|

|

|

Low maintenance costs

|

|

|

|

|

Cross-customer AI-Optimization

|

|

|

|

|

Continuous process

|

|

|

|

|

Secured sales of pyrolysis oil

|

|

|

|

|

Output quality

|

High

|

Low

|

High

|

|

Initial investment

|

High

|

Low

|

Low

|

|

Cost of labor

|

High

|

Low

|

Low

|

|

Energy consumption per liter

|

Low

|

High

|

Low

|

Disclaimer: Multiple sources were used to evaluate the information, which is presented according to specifically collected categories for the purpose of simplicity. If you are interested in the background or do not agree with any part of the information presented, please get in touch with us. Source: Elaboration by Biofabrik.

Introducing the WASTX Plastic

The Modular Recycling Plant

Introducing the WASTX Plastic

The Modular Recycling Plant

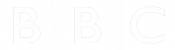

With our technology we offer a sustainable and profitable solution for plastic recycling.The decentral container-based pyrolysis plant is capable of processing otherwise non-recyclable, dirty, partially mixed as well as post-consumer polyolefins into oil.

The smallest unit can process one ton of plastic waste per day and can be upscaled as requested due to its modular structure. It requires 0.5 kWh of energy to process 1 kg of waste.

The decentral container-based pyrolysis plant is capable of processing otherwise non-recyclable, dirty, partially mixed as well as post-consumer polyolefins into oil.

The smallest unit can process one ton of plastic waste per day and can be upscaled as requested due to its modular structure. It requires 0.5 kWh of energy to process one kilogram of waste.

Known from:

Represented in

Up to

* depending on the feedstock

Currently

01 Customized Pretreatment of Plastic Waste

Depending on the highly diverse input materials available, we offer a customized pretreatment consisting of a suitable shredder, a washer and a centrifugal dryer. On the one hand, this ensures a high quality of oil and, on the other hand, enables a highly efficient pyrolysis with a recycling rate of approximately 85 %.

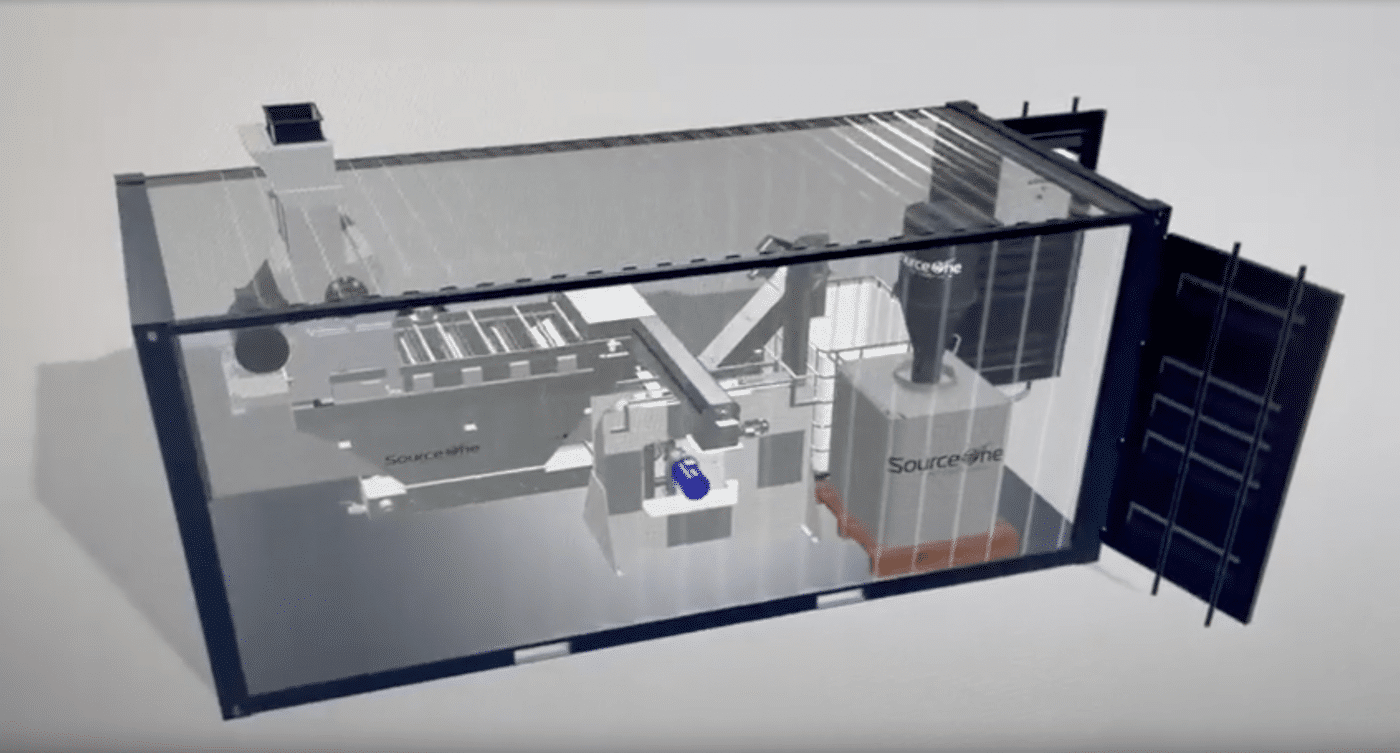

02 High-tech Chemical Recycling Process

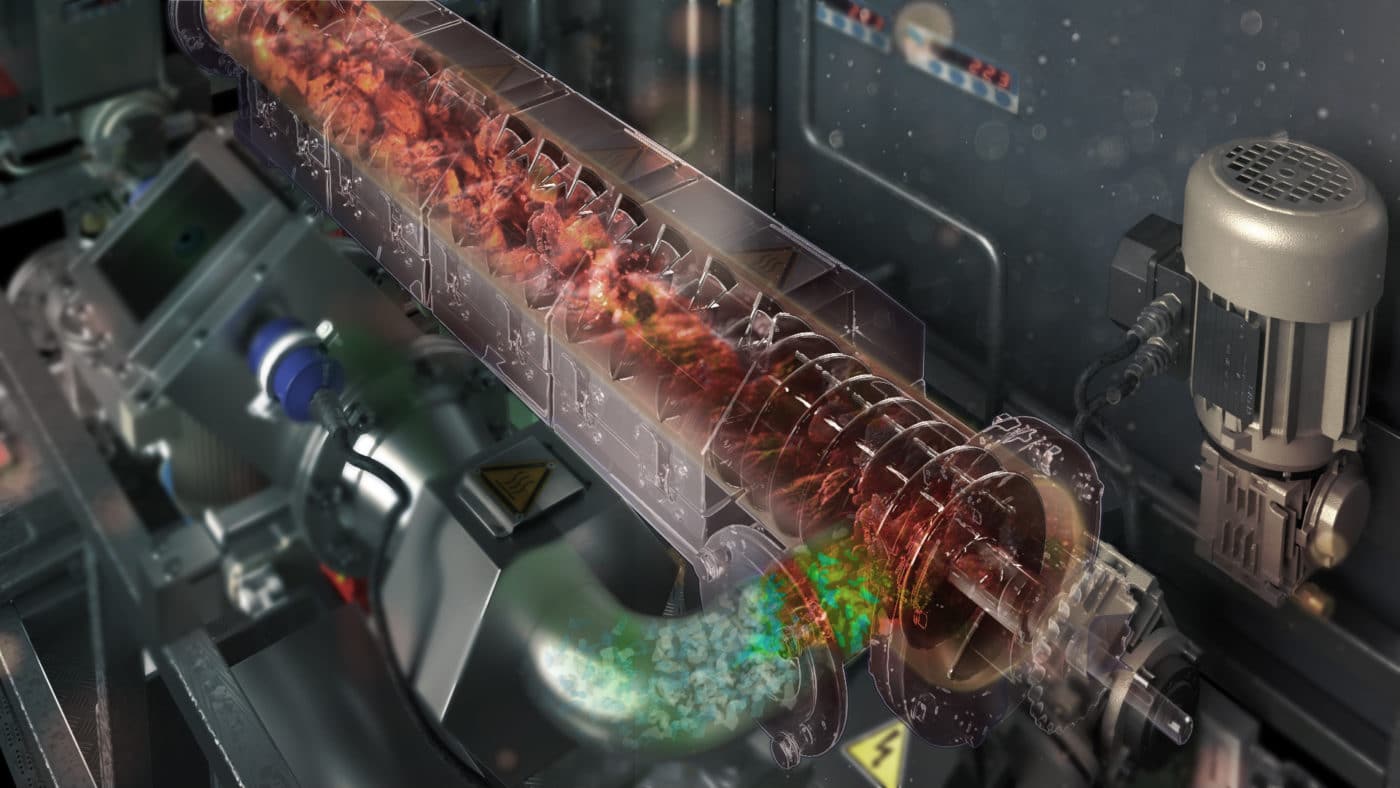

03 Creation of Valuable Recycling Oil

The monomers can be classified as secondary raw material or synthetic crude oil. In general, we secure the sale of recycling oil to the petrochemical industry, where it is used to produce new plastics. Through global contractual agreements with major players, we secure all oil sales while closing the material cycle loop. Even for special use cases or geographical peculiarities, the WASTX Plastic offers a strong added value, as the oil can be directly converted into electricity.

Our Clients are Convinced

Of all the people who saw the plant (WASTX Plastic P250), there was not a single person who was not surprised by the way the plant runs, how cleanly it operates, and the fact that we consistently run it on 70% of our own power, even without the oil we generate in the system.

Tim StClair-Pearce

Case Study: From One to Fifty Plants by 2025

Our exclusive distributor QMRE in Kent, UK, took delivery of the very first WASTX Plastic plant from Biofabrik in October 2020. Their plant is a WASTX Plastic P250, which was originally designed for showcasing purposes. However, QMRE has taken the collaboration to a higher level and therefore operates the plant on a daily basis. Furthermore, they are maintaining a local lab for oil testing.

In February 2022, QMRE is planning to start its first commercial project with the delivery of a WASTX Plastic P1000. By 2025, QMRE targets to build 50 recycling sites across the UK with processing capacities of 5-10 tons per day.

Advantages of the

WASTX Plastic

Advantages of the WASTX Plastic

Extremely efficient

1 kilogram of plastic waste becomes 1 liter of recycled oil

Highly-

profitable

A problematic waste material becomes a valuable product

Wide feedstock spectrum

Customized pretreatment enables processing various plastics

Scalable

Modularity makes usage feasible from small to large scale operation

Decentral

Application anywhere through a container-based design

Pay as you go

We offer different financing options depending on your preference and credit rating

The WASTX Plastic as a Business Model

More Than a Recycling Plant

With Biofabrik’s WASTX Plastic not only a pyrolysis plant is delivered, but a complete business concept. It includes logistics, product trade within our contractual agreements and billing, which refinances itself within a very short time. The easy-to-operate and highly automated plant requires neither extensive personnel nor special previous knowledge.

Video: Planned operating site of a WASTX Plastic P5000

Request More Information

plant visits, please register using the form below.