Compared to other types of polymers, polyolefins generally have a shorter life cycle because they are usually used for single-use products. Moreover, polyolefins are often incinerated, illegally dumped in the oceans or disposed in landfills.

Our WASTX Plastic technology offers a sustainable and profitable way of polyolefine recycling and turns problematic plastic waste into a valuable raw material.

Compared to other types of polymers, polyolefins generally have a shorter life cycle because they are usually applied for single-use products. Therefore, polyolefins are often incinerated, illegally dumped in the oceans or disposed in landfills.

Our WASTX Plastic technology offers a sustainable approach to profitably recycle polyolefins and turn problematic plastic waste into a valuable raw material.

Compared to other types of polymers, polyolefins generally have a shorter life cycle because they are usually used for single-use products. Moreover polyolefins are often incinerated, illegally dumped in the oceans or disposed in landfills.

Our WASTX Plastic technology offers a sustainable and profitable way of polyolefine recycling and turns problematic plastic waste into a valuable raw material.

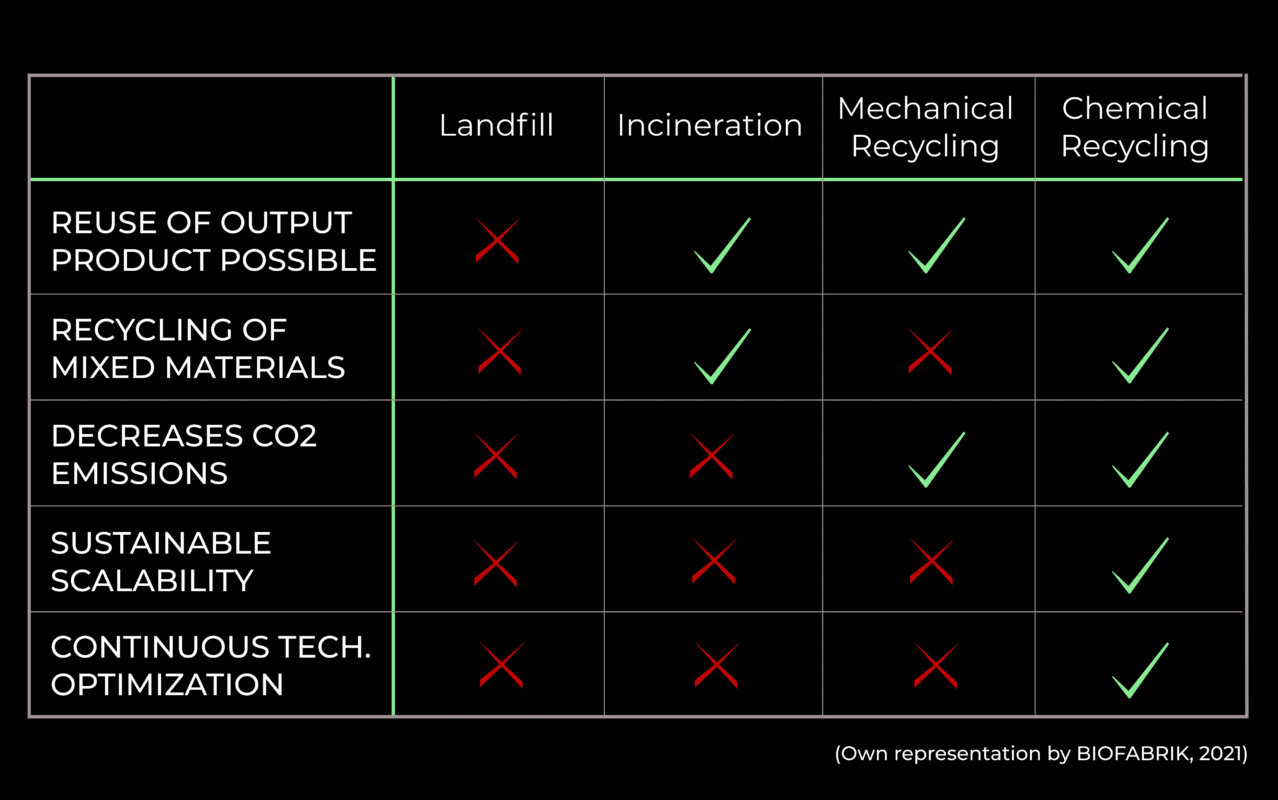

Polyolefins account for almost 60% of all plastic ever produced (Geyer et al., 2017). Common recycling methods for polyolefins are either landfills, incineration, or mechanical recycling.

Nevertheless, materials such as packaging materials, which are mainly made of polyolefins, have extremely low recycling rates, despite accounting for up to 40% of the collected waste in landfills. The main reason for this is a high degree of contamination due to impurities or multilayer material that cannot be separated.

With our technology the WASTX Plastic we offer a sustainable and profitable solution for the recycling of polyolefins.

The WASTX Plastic is a decentral, container-based pyrolysis plant, that is capable of processing otherwise non-recyclable, dirty and partially mixed post-consumer plastic waste into oil. The smallest unit we offer has a processing capacity of one ton of per day and can be upscaled as needed thanks to its modular design. It requires 0.5 kWh of energy to process one kilogram of waste.

The decentral container-based pyrolysis plant is capable of processing otherwise non-recyclable, dirty, partially mixed as well as post-consumer polyolefins into oil.

The smallest unit can process one ton of plastic waste per day and can be upscaled as requested due to its modular structure. It requires 0.5 kWh of energy to process one kilogram of waste.

Represented in

Up to

* depending on the feedstock

Currently

Pyrolysis is a depolymerization process in which plastic products are heated to temperatures of up to 500°C in the absence of oxygen to break down the polymers into monomers. The monomers can be classified as secondary raw material or synthetic crude oil. In general, we recommend selling the oil to the petrochemical industry, where it is used for the production of new plastics. This is both highly profitable and a contribution to closing the material cycle.

Coatings and impurities of plastic waste make mechanical recycling often difficult or even impossible. In the majority of times a landfill or incineration is the only option. The WASTX Plastic’s patent-pending chemical recycling process is particularly insensitive to interfering materials and precisely targets the types of plastic that make up the bulk of today’s plastic waste problem.

The German Federal Environment Agency states that around 85% of all plastic waste in Germany is post-consumer waste, which usually cannot be recycled mechanically. The patent-pending reactor design enables the WASTX Plastic to process even multilayer films and contaminants such as paper and food scraps.

The recycling of agricultural foil is complicated due to increased levels of contamination and moisture. Therefore, incineration and landfilling is usually the end-of-life phase. By applying our technology, we are able to reduce impurities and moisture already in the pretreatment stage. This enables profitable and sustainable recycling of agricultural films.

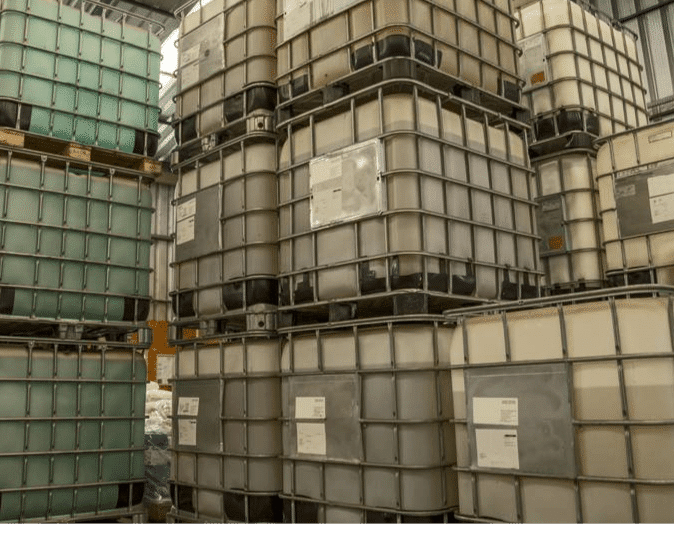

IBC tanks as well as rain barrels are usually used for storage of waste materials, liquid waste, sands and grains or other liquids. In the end-of-life phase of these containers, heavy contamination and large size make the recycling process both costly and complex. With our chemical recycling technology IBC containers can be easily shredded and impurities and moisture reduced already in the pre-treatment phase.

Coatings and impurities make mechanical recycling difficult or impossible. In the majority a landfill or incineration is the only option.

WASTX Plastic’s patent-pending chemical recycling process is particularly insensitive to interfering materials.

The German Federal Environment Agency states that around 85% of all plastic waste in Germany is post-consumer waste, which usually cannot be recycled mechanically. The patent-pending reactor design enables the WASTX Plastic to process even multilayer films and contaminants such as paper labels and food scraps.

The recycling of agricultural foil is complicated due to increased levels of contamination and moisture. Therefore, incineration or landfilling is usually the end-of-life phase. By applying our technology, we are able to reduce impurities and moisture already in the pretreatment stage. This enables profitable and sustainable recycling of agricultural films.

IBC tanks as well as rain barrels are usually used for storage of (hazardous) waste materials, liquid waste, sands and grains or other liquids. Therefore, heavy contamination and large size make the recycling process both costly and complex. With our WASTX Plastic, in the pretreatment stage already, IBC containers can easily be shredded and impurities and moist can be reduced.

To request an offer, access more information, receive an ROI calculation, or discover our plant visits, please register using the form below.