Biofabrik and ERMAFA: Scalable Solutions for Infectious Waste

Discover the synergy of Biofabrik and ERMAFA in the revolutionary WASTX Cleanic powered by MACS – a leap forward in sustainable infectious waste disposal.

Known from:

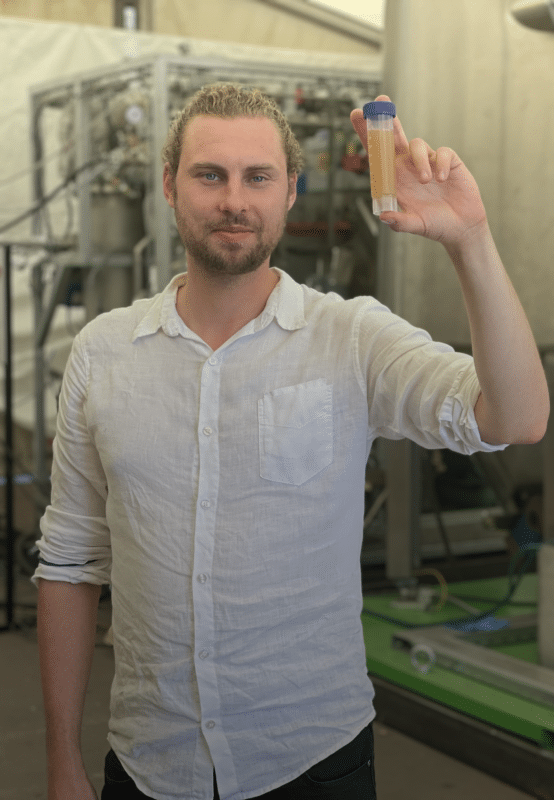

The Biofabrik develops scalable solutions to critical environmental problems. The Planet’s Company refers to the company our planet would create itself if it could.

Since the establishment of the Biofabrik Group in 2011, we have researched, improved and launched numerous technologies and products. Among them:

Since the establishment of the Biofabrik Group in 2011, we have researched, improved and launched numerous technologies and products. Among them:

THE WASTX PLASTIC

Chemical recycling

We want to contribute to a world in which plastic waste is not a critical environmental problem but a valuable resource. A world in which it is more economical to mine landfills instead of continually building new ones, and in which the garbage eddies in the oceans are considered the world’s largest oil fields.

THE BIOREFINERY

Amino acids from pasture grass

However, the vision of Biofabrik goes far beyond the plastic waste problem. We want to become the leading think tank for environmental issues and invest profits in researching more and more new environmental technologies. Everything started with the Biorefinery.

THE WASTX SNOWFLAKE

Mechanical recycling

Combining various waste-to-value and energy-from-waste technologies and approaches, we extract the maximum benefit from waste materials. The WASTX SNOWFLAKE is the latest product that can be used both as a pretreatment stage and as a stand-alone, mobile mechanical recycling plant.

THE WASTX OIL

Waste oil recycling

Combining various waste-to-value and energy-from-waste technologies and approaches, we extract the maximum benefit from waste materials. The WASTX Oil is dedicated to a highly underestimated environmental problem: waste oil. Using the technology, waste oils can be recycled sustainably.

With certified partners in 36 countries to date, our customers receive on-site, all-round service from a single source – in the local language, with fast service times and trained by us in Germany. We are currently represented in the following countries:

In addition to internationally active distributors, we are also looking for development partners for our global series production. Here you can apply for our recurring partner event:

April 15, 2024

Explore the future of hazardous waste management with WASTX Cleanic! Witness a live demonstration of our cutting-edge decontamination plant, tackling medical waste with efficiency and sustainability.

April 16, 2024

Experience a biomass pyrolysis plant in action at a commercial operation site. Join us to witness a live technology demonstration and gain valuable insights into its economic and ecological benefits.

More dates will follow soon

Sign up for the official demo of the new generation of the WASTX Plastic technology. You can witness how plastic waste turns into oil directly from our partner’s site – secure your spot now!

Discover the synergy of Biofabrik and ERMAFA in the revolutionary WASTX Cleanic powered by MACS – a leap forward in sustainable infectious waste disposal.

Discover how Eagle Technologies and Biofabrik revolutionize plastic recycling with the WASTX Plastic pyrolysis plant for a greener future.

Explore how the Impact Family addresses pressing global challenges like CO₂ emissions and soil degradation. Discover the transformative potential of Biomass Pyrolysis and Biochar for a sustainable future.