Share this post on Social Media

The first biorefinery of the Green Refinery Biofabrik goes into operation after years of research. The technology produces vegetable amino acids and healthy fertilizers from renewable raw materials and thus makes an important contribution to solving the global nutrition problem.

According to current estimates, around 10 billion people will live on Earth by the middle of the century. At the same time, the per capita consumption of food will continue to rise due to the rising standard of living in emerging markets. For this reason, we need to make optimal and sustainable use of the constant areas of land available for cultivation.

The biorefinery uses pasture grass and meadow grass as a completely undervalued raw material for the food and chemical industries. In addition to rare, vegan and freely available amino acids, valuable natural minerals and carboxylic acids necessary for many applications are produced – produced in the European Union and free of genetically modified material.

While the food industry is thus offered a healthy alternative to the amino acids often produced from animal residues, the chemical industry can produce products from renewable raw materials for which finite fossil raw materials were previously necessary – in addition to biological fertilizers, for example, biodegradable plastics, vegan cosmetics and herbal medicines.

Already since 2006 a team around Dr. Horst Steinmüller has been researching with in Switzerland and Austria to the foundations of biorefinery. From 2009 in cooperation and from 2013 under the management of the Biofabrik, the technology was transferred to series production, the first locations were developed, the business model and marketable products were developed.

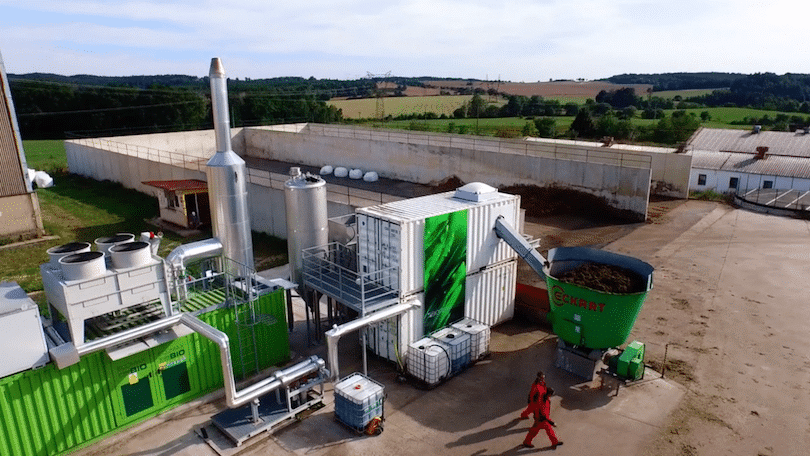

The refinery works in symbiosis with grass processing industries such as biogas plants, which have the necessary infrastructure as well as large quantities of the raw material. Only the relevant recyclable material is removed from the grass, the remaining biomass is used as usual in the biogas plant.

Biogas plants generate an additional source of income without investment or additional expenditure, which makes them independent of government subsidies and profitable for the first time in their own right. The biorefinery is therefore seen as a possible contribution to the rescue of the ailing biogas industry, which, thanks to this technology, could move away from maize monocultures and towards healthy pasture grass.

The biorefinery has the potential to change our predominantly economically motivated agriculture towards sustainable agriculture and to provide millions of people with healthy food. In addition to pasture grass, we will also develop other, previously untapped sources of raw materials for this purpose in the future.

Economies of scale and continuous process improvements will create a sustainable, biological alternative to fossil fertilizers. In addition, we want to develop a nutrient complex that can be dispensed in third world countries to meet the daily needs of school children in particular for essential amino acids and minerals. and I’ll cover for you.

<pclass=”bodytext”>In the long term, a worldwide network of sites is to be created for this purpose, which will propagate independently through its symbiosis of additional revenues for agriculture and the solution of one of the greatest problems of future generations – the lack of fossil fertilizers.</pclass=”bodytext”>

More than 100 locations in Germany have already been contracted. With the expansion to unsilicate grass species and other protein-containing residues, the technology can provide new sources of income, jobs and prosperity at any location in the world in the future.

Follow us on Facebook and be the first to know where this long journey together leads us.