Share this post on social media

Nowadays, there are a lot of environmental challenges that need to be tackled to safeguard the health of our planet, as we make our way towards a greener future. Even though the awareness on the subject is steadily growing, there seems to be one issue that keeps slipping under the radar – waste oil mismanagement.

In the United States alone, more than 18 billion barrels of waste oils are generated every year from all sorts of industrial activities, according to the American Petroleum Institute (API).

The improper handling and disposal of waste oils can have severe environmental consequences, yet it remains a relatively unknown problem globally. In this blog post, we will shed light on this issue and explore the potential solutions to mitigate its impact.

A post by Alice Frassin

Mismanagement of waste oil simply indicates improper handling, storage, transportation, or disposal of used or waste petroleum-based or synthetic oil that is no longer suitable for its original intended purpose.

These oils, regardless of what industries they are generated by, are often mishandled or incinerated.

Mishandling includes improper storage in open containers or damaged tanks, illegal dumping in unauthorized locations, spilling or leaking during transportation due to inadequate labeling and packaging, mixing with hazardous materials, and failure to comply with local regulations.

Incineration, while being one the most common methods used to dispose of waste oil, can also be considered a type of mismanagement. Not only does it contribute to air pollution, it also marks the end of the life cycle of the discarded oil, resulting in poor resource recovery and recycling.

One might assume that as the global transition to renewable energy accelerates, the waste oil problem would gradually diminish.

However, the reality is more complex.

While the implementation of renewable sources is increasingly gaining momentum and the use of fossil fuels is apparently being reduced, oil remains a critical energy source in many sectors. As a result, there is consistent production and mismanagement of waste oil.

To tackle this growing challenge, it is necessary to explore new solutions that can effectively manage and recycle used oil, while minimizing its impact on the environment, wildlife and human health.

The world is currently facing a waste oil problem of enormous scale.

As already mentioned, millions of tons of waste oil are generated globally every year, with a significant portion being inadequately disposed of, leading to severe environmental and health hazards.

The industries that contribute to this problem include manufacturing, automotive, energy production, agriculture, mining, transportation and shipping.

One sector that often evades attention when it comes to waste oil generation, is the shipping industry.

During regular operation of industrial shipping activities, vessels often produce significant quantities of marine sludge as a byproduct, which is discharged ashore or incinerated. Its mismanagement raises the risk of oil spills and high environmental hazards.

Did you know?

According to the International Tanker Owners Pollution Federation (ITOPF), there have been more than 800 spills from ships since 2000, with an average of 1 spill every 3 days. The shipping industry alone produces over 5 million tons of waste oil every year - that's enough to fill up about 15 Olympic swimming pools!

As reported by the European Maritime Safety Agency, oily residues generated by container ships each day are approximately 1-3% of the total amount of fuel used.

It is estimated that a large container ship of 1 metric ton capacity requires up to around 250 tons of marine fuel per day to operate, which means that they generate up to 5 tons of sludge per day.

With this calculation, considering that there are more than 5500 container ships operating every year, the numbers add up quickly, and the amounts of waste oil generated are staggering (Statista Research Department, 2022).

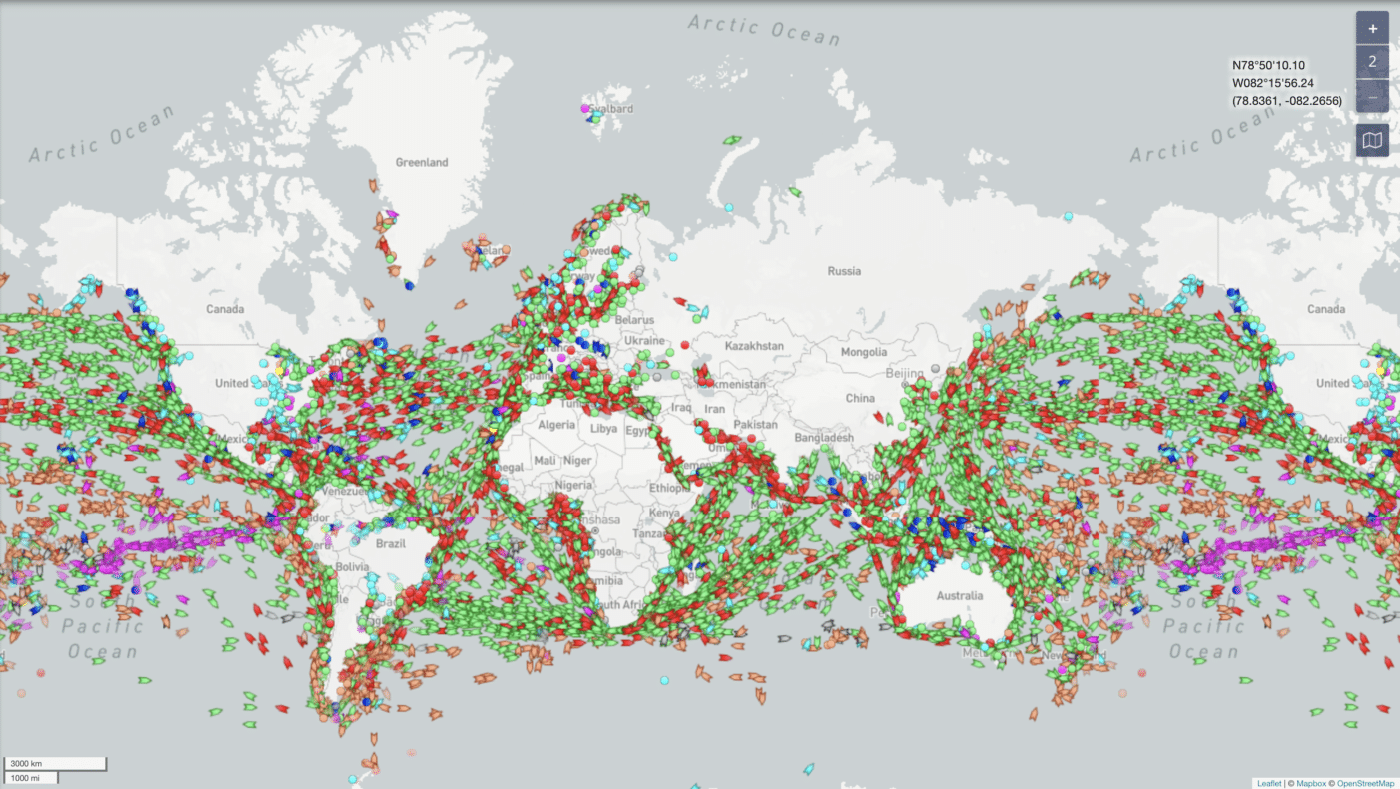

To have a clearer idea on the matter, this visual representation of marine traffic clearly portrays the high level of real-time activity and congestion that is taking place in our waterways every day, from all sorts of vessels. And container ships are only the green ones!

By observing the map, you can get an insight into the scale and complexity of the global maritime industry, including the vast volume of ships circulating and the rough estimate of how much waste oil is being produced on a daily basis.

And yet, awareness of this issue remains low, particularly in port activities. A large portion of the world’s population might not be even aware of how much waste oil exists in the first place, let alone what happens when it gets spilled into our waterways and spread in our surroundings.

Over the years, the wind power industry has grown significantly, so much that wind turbines are now a normal part of the landscape in many parts of the world. However, the operation of these turbines requires a great amount of oil that needs to be replaced at a high frequency.

According to statistics, each turbine consumes approximately 1 liter per hour during operation, which adds up quickly when you consider that there are thousands of turbines across multiple locations around the world! Additionally, waste oil from wind parks can also originate from the use of cranes and trucks.

Overall, this waste is often not adequately managed: the most common methods for disposal are either landfilling or incineration, and both options have their downsides and high environmental repercussions.

The mining industry is one of the largest industries in the world and is responsible for extracting valuable minerals, metals, and other resources from the earth. It is a vital sector for the global economy, but it is also associated with significant environmental impacts, including the production and mismanagement of waste oil.

Mining operations rely heavily on equipment which generates a significant amount of waste oil as a byproduct containing harmful substances such as heavy metals and toxic chemicals.

According to a report by the International Council on Mining and Metals (ICMM), the mining industry generates around 1% of the world’s waste oil. The report estimates that the industry produces about 10 million barrels of used oil each year, which is equivalent to 1.6 billion liters of waste oil.

The transportation and logistics industry, especially in the case of trucks, is another significant source of waste oil. Trucks strictly rely on diesel fuel to work, and this fuel can lead to the production of waste oil through engine wear and tear, as well as spills and leaks during transportation and fueling.

As reported by the U.S. Environmental Protection Agency, a typical 18-wheeler truck can produce between 10 and 15 gallons of used oil every 100,000 miles. This adds up quickly, as the trucking industry is responsible for transporting a significant portion of goods and materials across the globe.

Incineration, as previously mentioned, is currently the most common option for waste oil disposal. Ultimately, burning waste oil releases harmful gases and pollutants into the atmosphere.

Moreover, since incinerating plants are mostly of bigger size they have to be centralized and thus, far away, producing high transportation costs.

Even if there are cases in which waste oil is used as an alternative energy source in incinerators and not directly incinerated, it remains a less sustainable solution compared to recycling. Turning waste oil into diesel, for example, is a more efficient and less harmful way to recycle it.

As an alternative solution, one promising approach that has been proven beneficial, is decentralized recycling technologies and systems. By having a waste management process on site, these technologies can empower local communities to take ownership of their waste streams directly where it is generated.

Given the limitations of traditional waste oil management practices, many businesses are looking for more sustainable, efficient, and cost-effective solutions.

In cases like these, there is a strong need for new approaches that can be implemented locally, tailored to the specific needs of the site, and that addresses this issue more sustainably.

Decentralized recycling technologies, for example, are able to process the waste on-site, rather than transporting it to a centralized facility. This offers several benefits, such as reduced logistics costs, a lower risk of environmental contamination and increased efficiency.

At Biofabrik, we identified this issue and felt the need to address it. After realizing that this section of the market was not yet offering a viable and sustainable option to this challenge, we focused on developing recycling technologies that can be operated directly where the waste is generated and stored, with an increased efficiency.

The WASTX Oil technology is a decentralized mini-refinery that aims to tackle the negative environmental impact caused by waste oil mismanagement by recycling it profitably and efficiently.

Its modular design allows its adaptation and implementation in different scenarios, locations and industries. On the basis of specific use cases, the technology can be applied in different ways and customized to meet specific needs and fit different business models and recycle a variety of mineral-based oils.

Some of the possible applications could be in recycling marine sludge, port disposal, mining, tank cleaning and much more.